GEMSTONES GLOSSARY

Laboratory-grown gemstones

Laboratory-grown gemstones are stones grown and created in a science laboratory, man-made, rather than mined from the ground and from nature. They exist in two genres, laboratory-grown synthesized gemstones and laboratory-grown simulated gemstones.

Synthesized gemstones

A lab-grown synthesized gemstone shares identical optical and gemological qualities to natural mined gemstones. They have the same chemical composition and structure, hardness and durability, colours and brilliance to their natural mined counterparts. Synthesized gemstones can also have inclusions or perfect clarity.

Simulated gemstones

A lab-grown simulated gemstone shares similar optical qualities, colours and brilliance but have different gemological qualities to natural mined gemstones. They have different chemical composition and structure, hardness and durability to their natural mined counterparts. Simulated gemstones usually have perfect clarity and colour saturations, often with improved hardness and durability, except for diamonds. A simulated gemstone is usually chosen for its balance in optical qualities, durability and affordability.

Recycled gemstones

A recycled gemstone is a re-purposed natural, mined gemstone that has originated from estate or antique jewellery and private, personal collections. The natural gemstones are often recut and repolished, to be reset into brand new creations breathing new life into lost and forgotten jewels.

Natural gemstones

A natural gemstone is one that is naturally occurring in nature and mined from the ground around the world.

For almost all of our simulated diamond creations, it is possible to custom-made for you in laboratory-grown synthesized diamonds, or recycled natural mined diamonds. Please contact bespoke@anabelachan.com for more information.

PRECIOUS METALS GLOSSARY

24k gold

Gold purity content is categorized using the karat system. Pure gold is 24k, it is extremely soft, it bends, warps and scratches easily making it an unlikely metal for jewellery that needs to retain its shape.

18k gold

18 karat gold is made up of 75% gold and 25% alloy. This type of gold is referred to as 18 karat because 18 out of the 24 parts that make up the gold are pure gold. 18K gold is usually the most pure form of gold used for rings, watches and other wearable jewellery.

14k gold

14 karat gold is made up of 58.3% gold and 41.7% alloy, or 14 out of 24 parts gold. 14K gold is a popular gold for jewellery, its colour is slightly less saturated and intense than 18 karat gold, with greater durability and affordability.

18k gold vermeil

18k gold vermeil is a 2-3microns thick coating of 18k gold on sterling silver, usually 10-times the thickness of standard plating for greater durability, hardness and affordability.

Rhodium vermeil

Rhodium is a member of the platinum family, and rhodium vermeil is an electroplated coating of rhodium on sterling silver. Rhodium is a silvery-white, hard and corrosion-resistant precious metal that reflects 80% of light, giving one of the best sheens achievable on white gold or sterling silver jewellery.

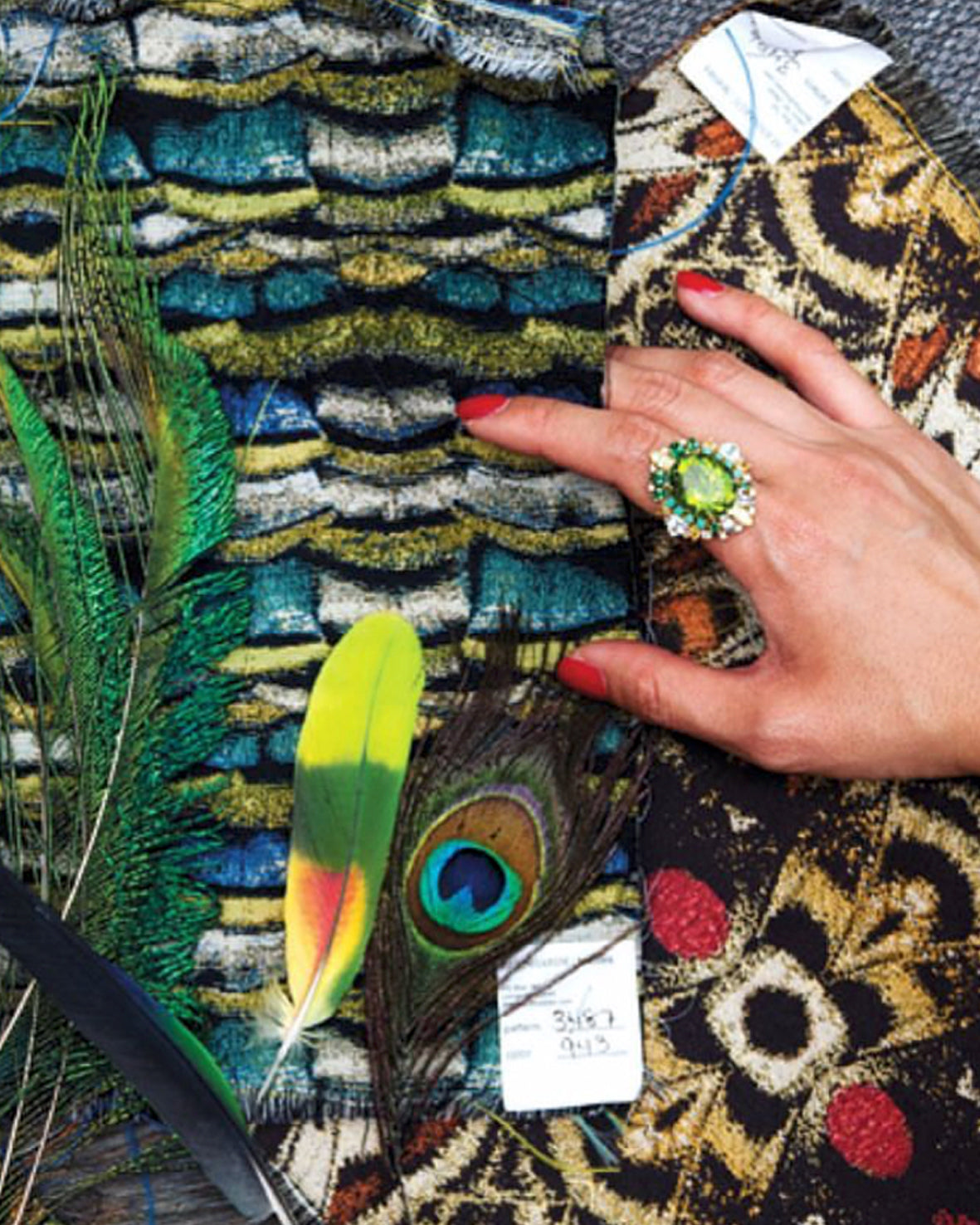

Recycled Aluminium

Our Aluminium Blooms Collection pioneers the use of recycled aluminium refined from soda cans, a lightweight silvery-white metal that can be cast into fine jewellery creations through the artisanal method of lost-wax casting. Aluminium can be coloured into a wide spectrum of hues through the process of anodizing and physical vapour deposition as used in the automobile and horology industries.

Recycled aluminium was first introduced in BLOOMS collection. Through a process of trial and error, BLOOMS is a project 2 and half years in the making that began in 2017. By taking waste aluminium drink cans as the base metal, the cans are cut up into small 1.5cm squares, then melted at approximately 600 degrees C (the colours printed on the outside of the cans disappear in the heat). Through a process of refining it to overcome the impurities, the molten aluminium is then poured into ingots (bars of metal cooled from the melted and refined aluminium), ready for casting. From the ingots onwards, similar to gold pebbles and bars, the process is the same as working with precious metals in jewellery, where we are able to create miniature sculptures through the ancient artisanal process of lost-wax casting.

The biggest challenge with recycling aluminium cans is the impurities in the metal that causes issues with porosity, an uneven texture and tiny pores in the surface of the finished piece. By refining the recycled aluminium, through a process of trial and error, we were able overcome this and actually take advantage of a controlled porosity that allow us to achieve greater colour intensity. The unusual, incredible psychedelic iridescent colours have been achieved using physical vapour deposition, known as PVD, the same technique used in the car industries to colour car bodies.

The results are creations of bold, dramatic and sculptural jewellery.