Iconic Creations

Turquoise Roi De Soleil Earrings

- ¥513,900

- ¥513,900

- Unit price

- / per

Turquoise Mermaid Ring - Gold Vermeil

- From ¥320,400

- From ¥320,400

- Unit price

- / per

- Gold Vermeil

- 18k Gold

Citrus Bloom Earrings

- ¥341,900

- ¥341,900

- Unit price

- / per

Emerald Sugarloaf Berry Ring - Gold Vermeil

- ¥305,300

- ¥305,300

- Unit price

- / per

- Gold Vermeil

Iconic Creations

Turquoise Roi De Soleil Earrings

- ¥513,900

- ¥513,900

- Unit price

- / per

Turquoise Mermaid Ring - Gold Vermeil

- From ¥320,400

- From ¥320,400

- Unit price

- / per

- Gold Vermeil

- 18k Gold

Citrus Bloom Earrings

- ¥341,900

- ¥341,900

- Unit price

- / per

Emerald Sugarloaf Berry Ring - Gold Vermeil

- ¥305,300

- ¥305,300

- Unit price

- / per

- Gold Vermeil

-

Holiday Gift Guide

Holiday Gift Guide -

Jelly Heart Resort Collection

Jelly Heart Resort Collection -

New In: Chlorophyll

New In: Chlorophyll -

New In: Fruit Gems™

New In: Fruit Gems™ -

Fine Jewellery

Fine Jewellery

- Fine Jewellery

- By Category

-

All Collections

-

Jelly Heart Resort Collection

Jelly Heart Resort Collection

-

Chlorophyll

Chlorophyll

-

Fruit Gems™

Fruit Gems™

-

Everyday Diamonds

Everyday Diamonds

-

AC X Miss Sohee

AC X Miss Sohee

-

Magma & Aurora

Magma & Aurora

-

Mermaid's Tale

Mermaid's Tale

-

Blooms!

Blooms!

-

Supernova

Supernova

-

AC x Robert Wun

AC x Robert Wun

-

Forbidden Fruit

Forbidden Fruit

-

Cupid's Bow

Cupid's Bow

-

Palms

Palms

-

Noir

Noir

-

English Garden

English Garden

-

Butterfly Orchard

Butterfly Orchard

-

Tutti Frutti

Tutti Frutti

-

Love Hearts

Love Hearts

-

Fleurs D'Elixir

Fleurs D'Elixir

-

Constellation

Constellation

-

Dark Forest

Dark Forest

-

Puppy and Kitty

Puppy and Kitty

-

The Morpho Bloom

The Morpho Bloom

-

![]()

-

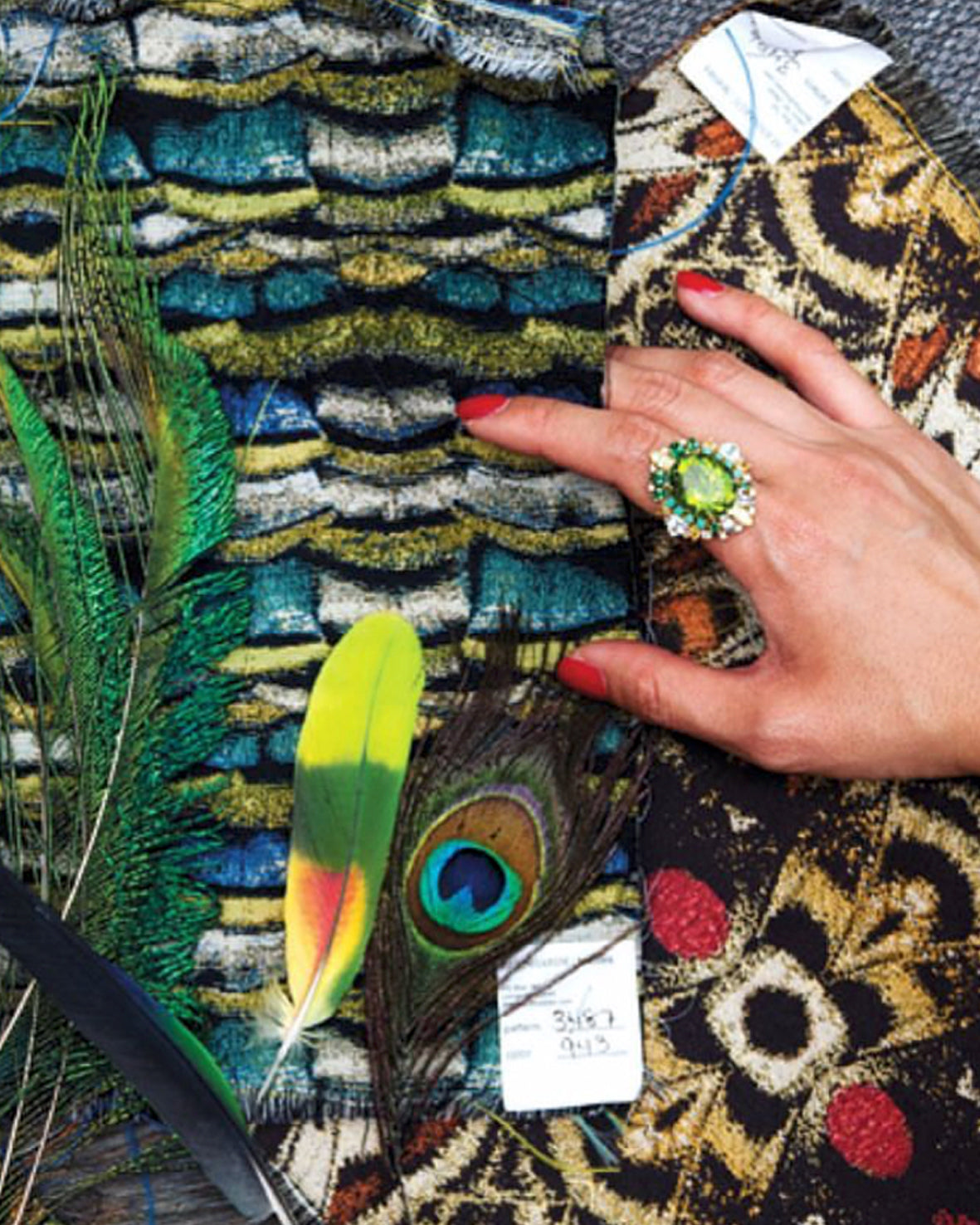

Anabela's Edit

Anabela's Edit

-

Haute Couture

Haute Couture

-

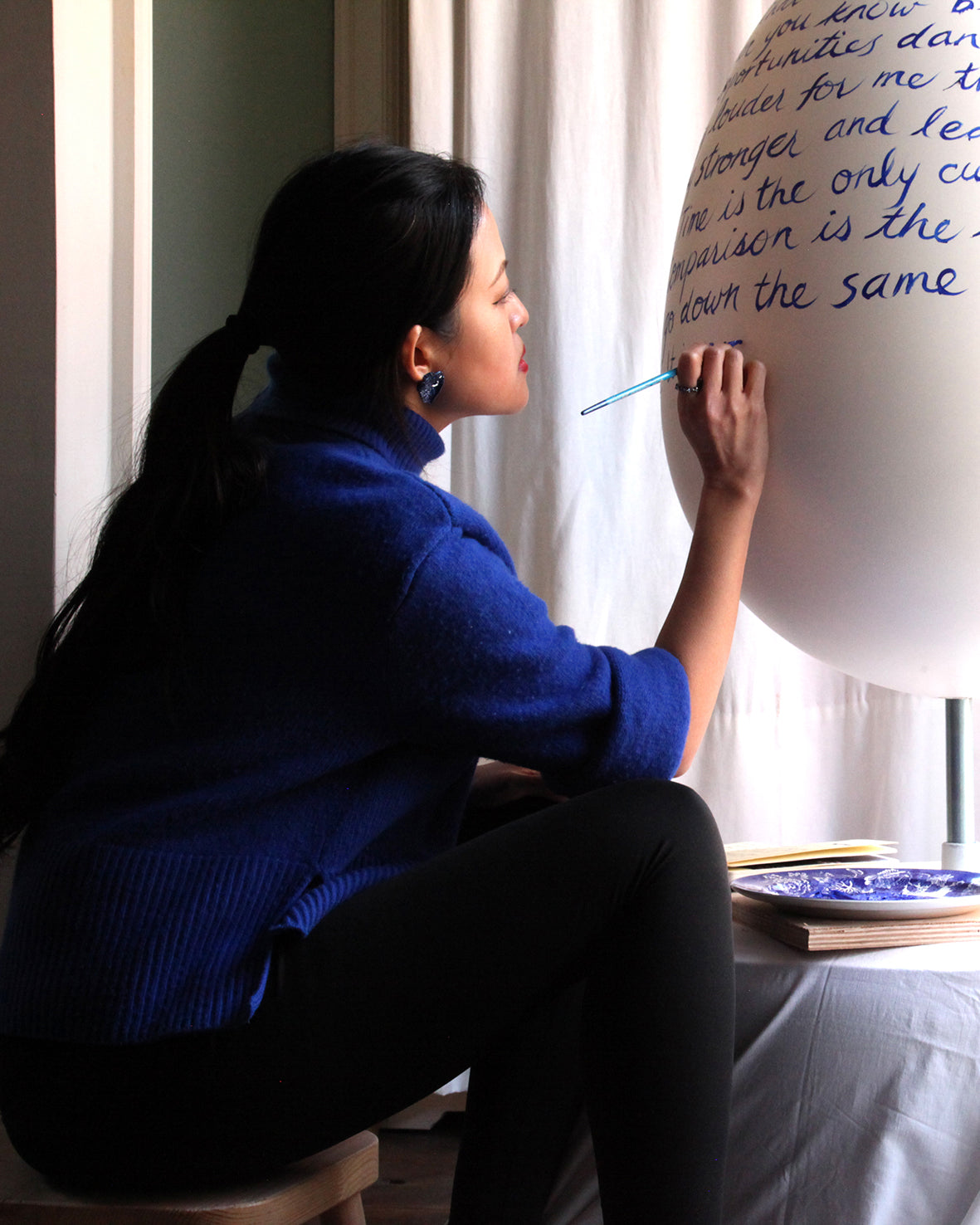

Bespoke Commissions

Bespoke Commissions -

Our Innovations

Our Innovations

-

Maison

Maison

-

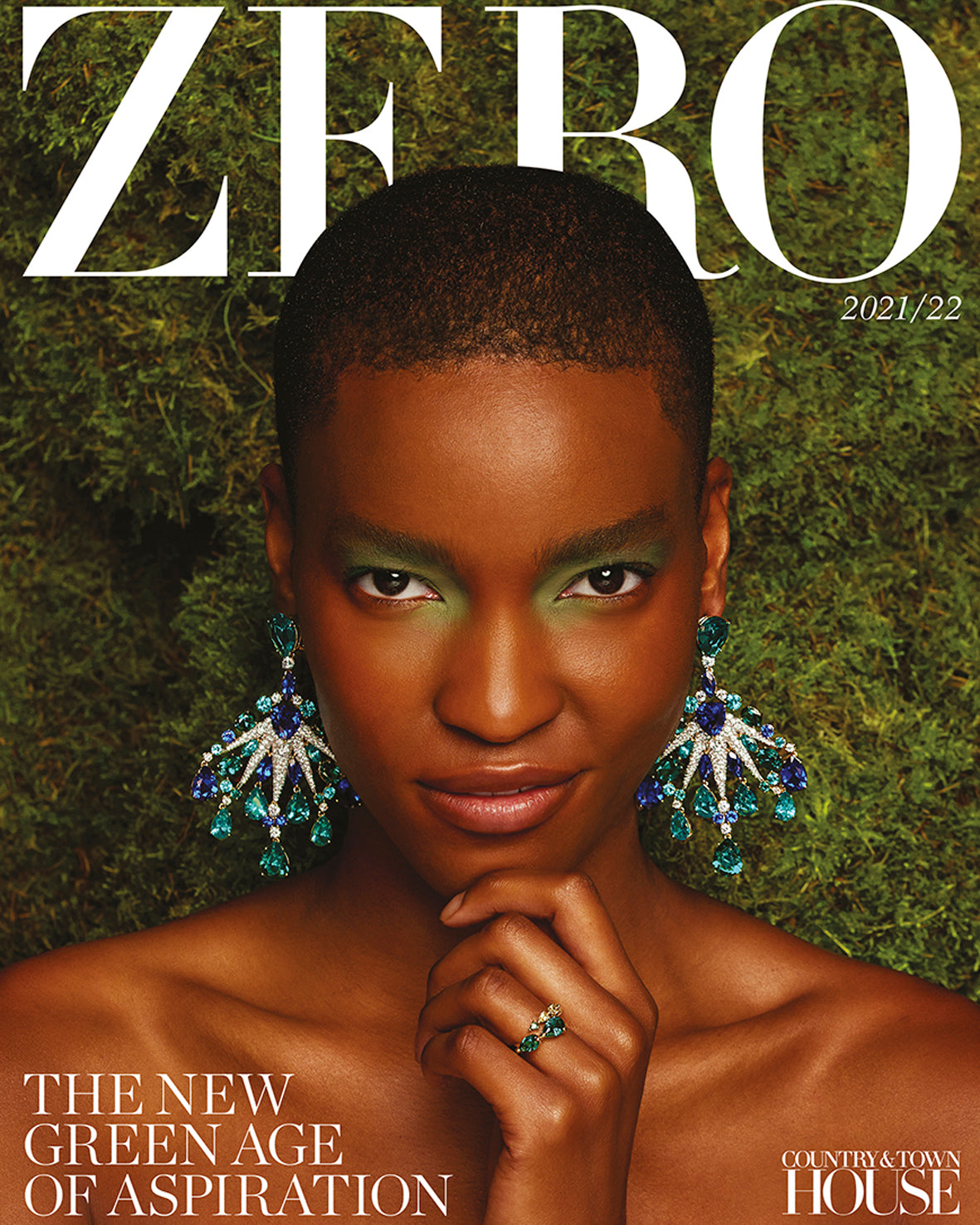

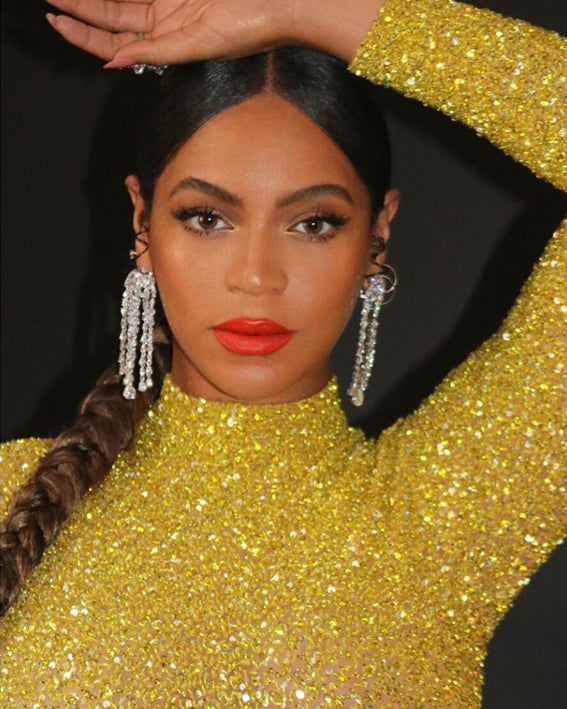

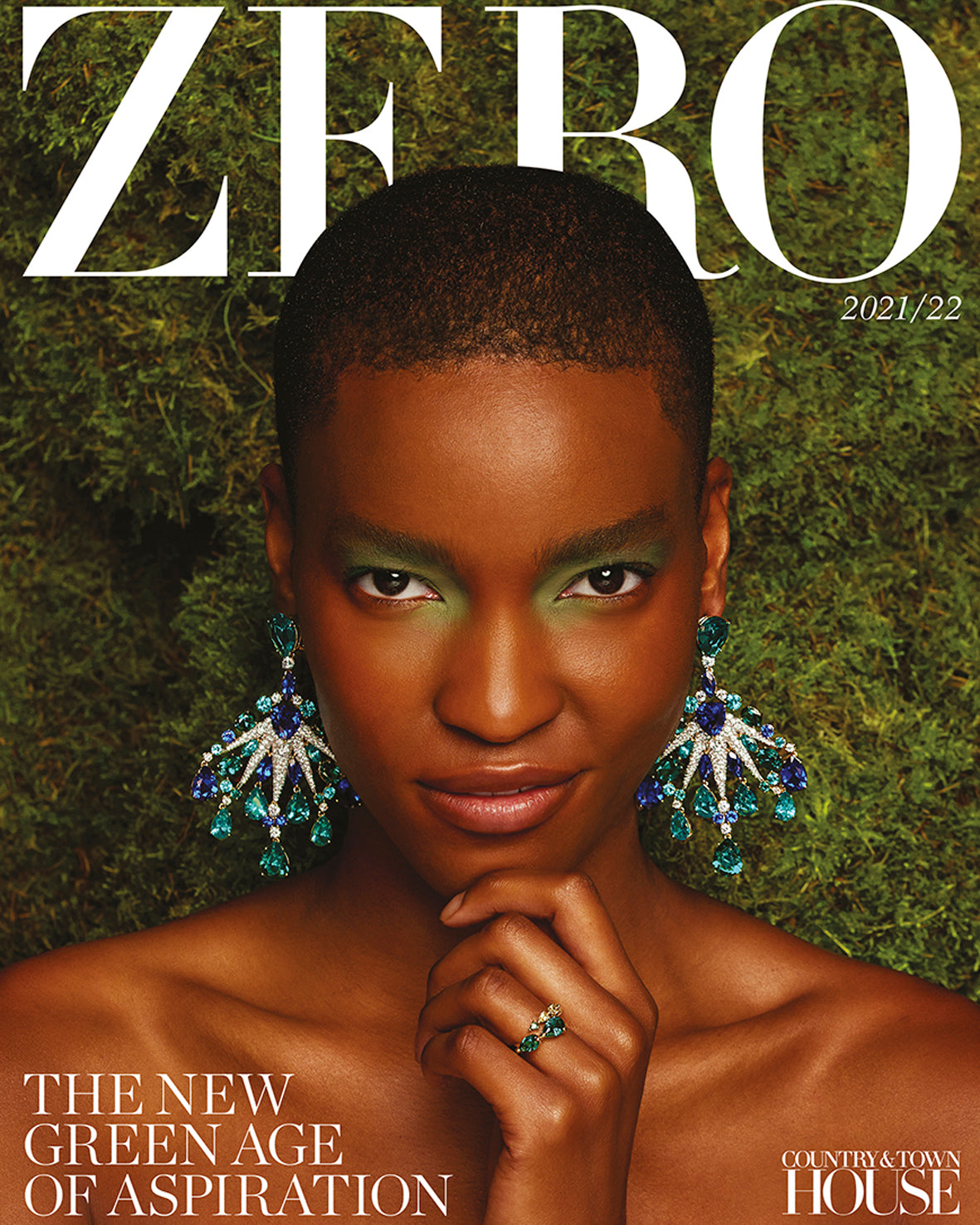

Press

Press

- Press

-

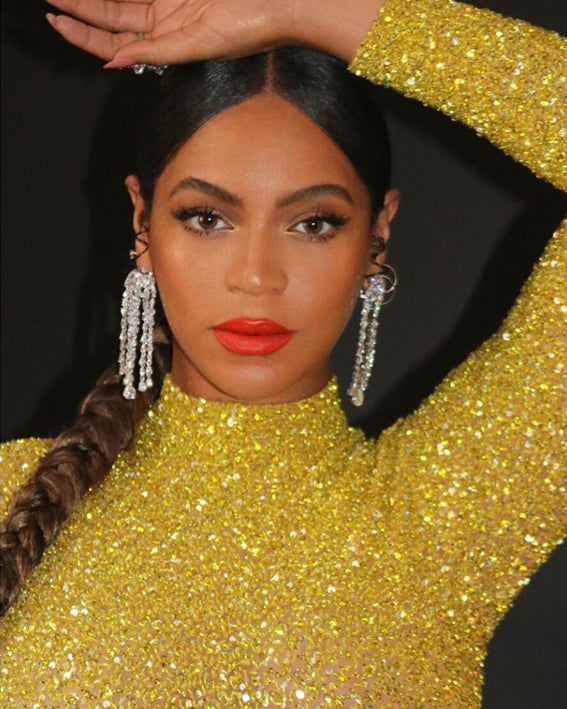

Stars in AC

-

Editorials

-

Films

-

Interviews

-

Collaborations

Collaborations

- Collaborations

- Haute Couture

- Discover all Collaborations

![]()

-

Art

Art

Anabela Chan 10th Anniversary Special Collection

Magma Atlantis Drop Earrings - Gold Vermeil

- ¥427,900

- ¥427,900

- Unit price

- / per

Aurora Butterfly Brooch

- ¥363,400

- ¥363,400

- Unit price

- / per

Magma Rose Studs - Gold Vermeil

- ¥219,300

- ¥219,300

- Unit price

- / per

Aurora Titan Earrings

- ¥427,900

- ¥427,900

- Unit price

- / per

Magma Butterfly Brooch

- ¥363,400

- ¥363,400

- Unit price

- / per

Aurora Poppy Earrings - Gold Vermeil

- ¥384,900

- ¥384,900

- Unit price

- / per

Magma Poppy Earrings - Gold Vermeil

- From ¥406,400

- From ¥406,400

- Unit price

- / per

- Gold Vermeil

- 18k Gold

Aurora Rose Studs - Gold Vermeil

- ¥219,300

- ¥219,300

- Unit price

- / per

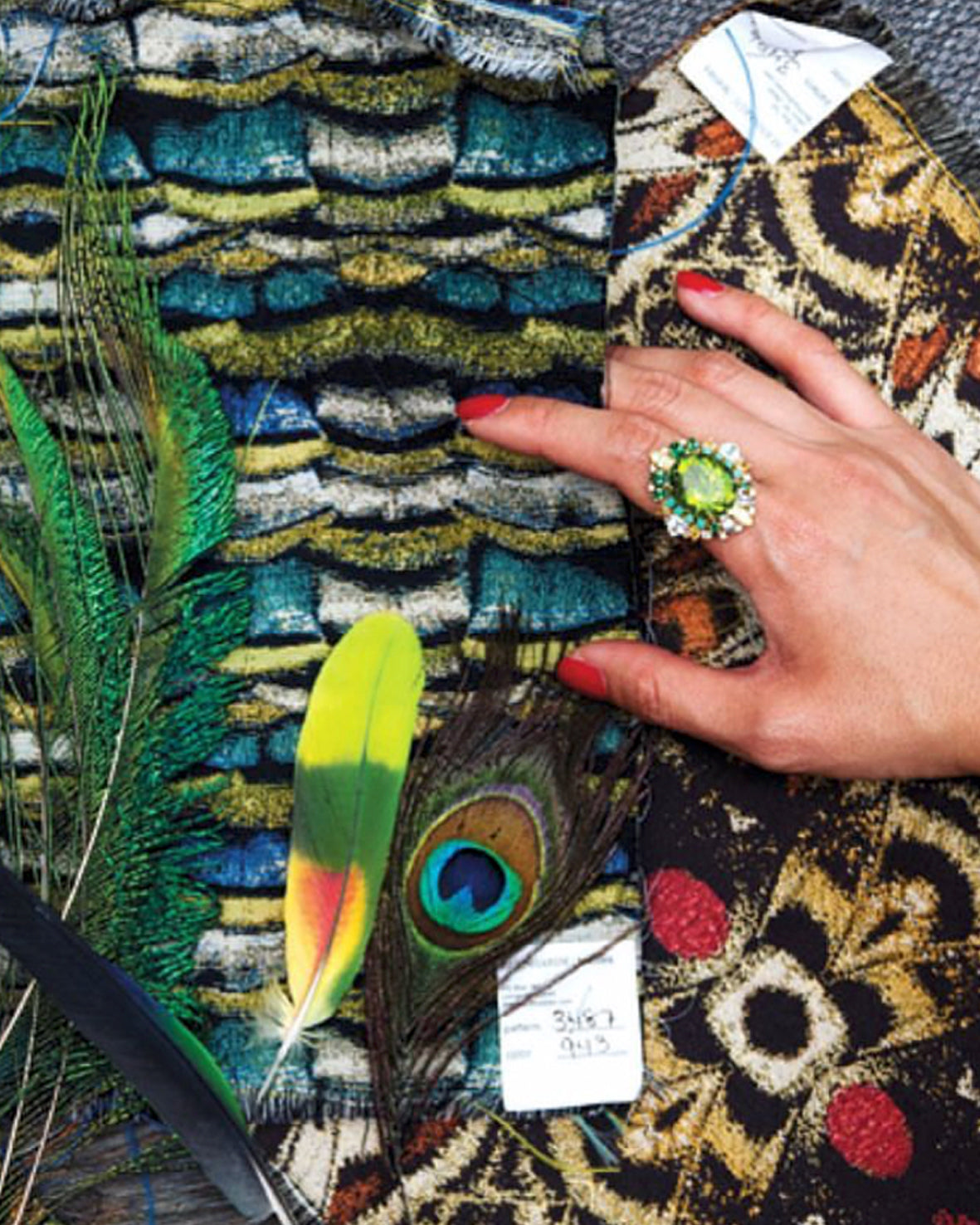

The Painterly technique in anodised aluminium.

To achieve a spectrum gradient with a ‘painterly’ effect where different colours flow into one another, it is similar to painting with pigments by hand. Let us explain why this is a challenge.

Aluminium is the second most widely used metal in the world and engineers use it for its lightweight and corrosion resistance. Anodising is an electrochemical process that develops an aluminium oxide coating on the surface of the aluminium, which gives it its colour and resistance, with a hardness equivalent of 9 on the Moh’s scale, second to diamonds. The anodizing process works by passing a direct current through an electrolytic solution, to allow the layer of aluminium oxide to form on the surface, and in the process open up ‘pores’ in the metal to allow for the colour pigments to be absorbed. The challenge with achieving a gradient colour is that the dye process requires submerging the piece into a chemical bath for a controlled length of time, which usually gives a single colour, so in order to achieve a gradient ombre effect, like an alchemist we created our own pigmented solution with a unique consistency that allows us to play with the ‘painterly’ effect organically by hand, with each creation a unique edition.

PHILANTHROPY

- Choosing a selection results in a full page refresh.