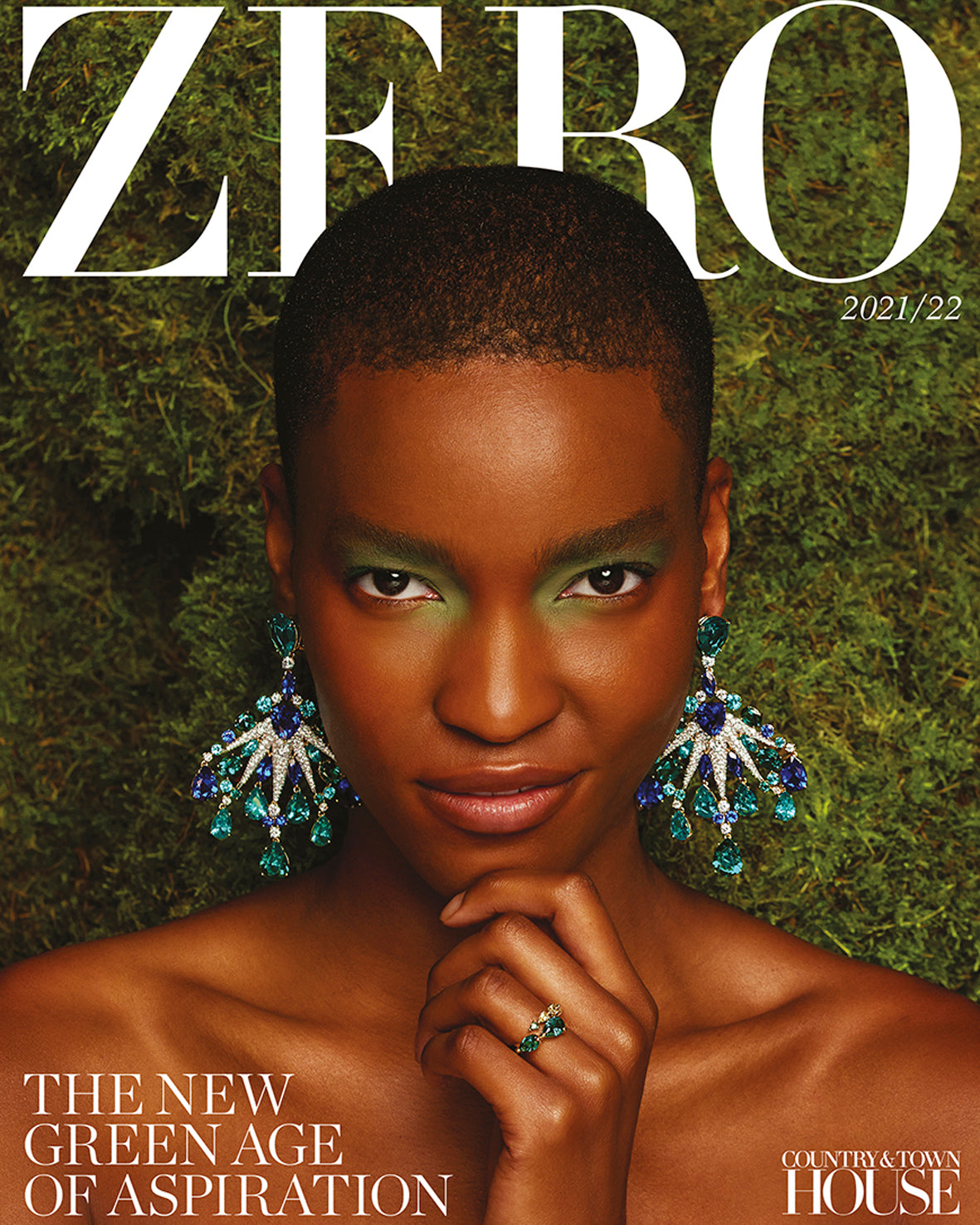

Anabela Chan Joaillerie x the Jewellery Cut

The Jewellery Cut

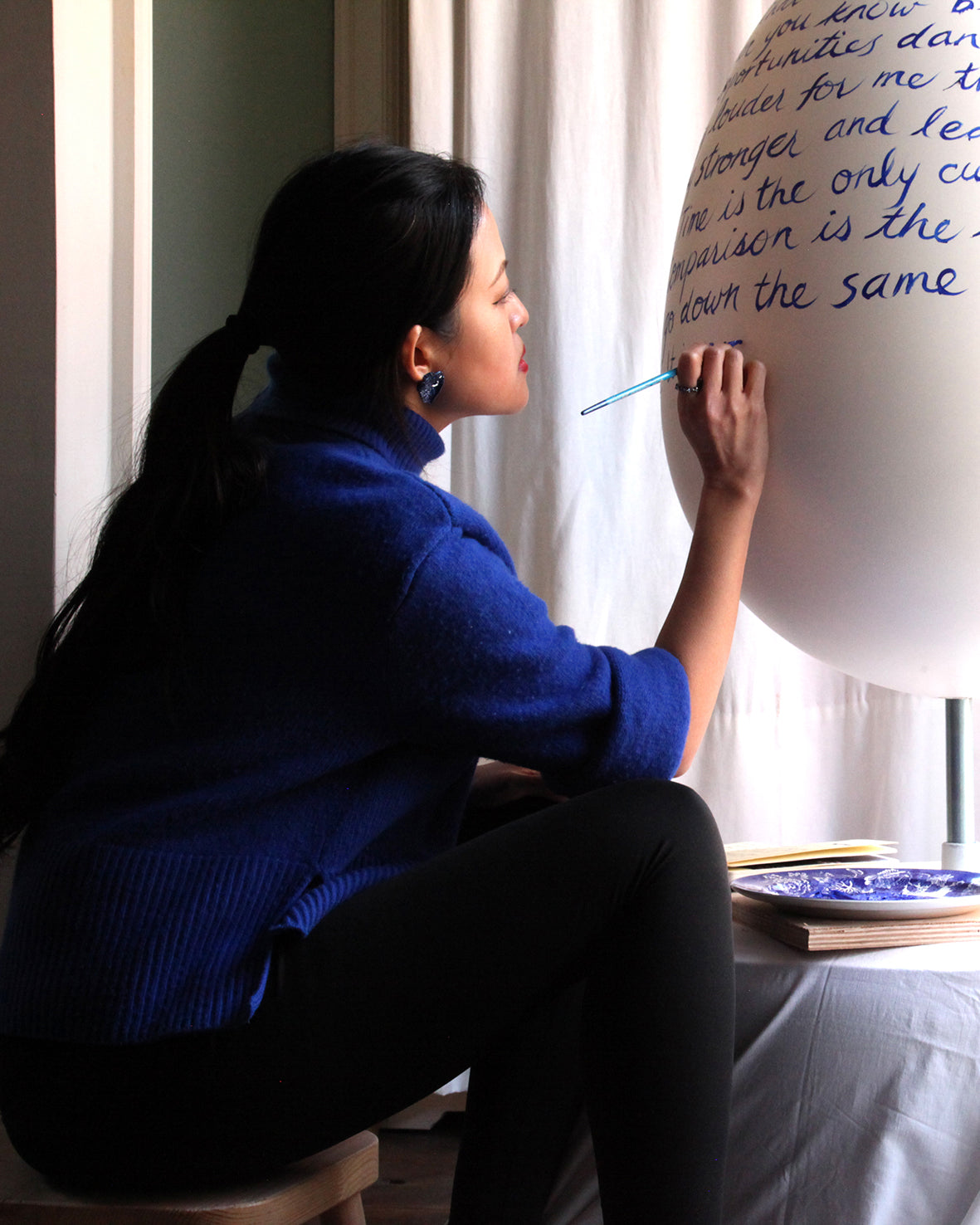

Anabela Chan is turning drinks cans into luxury jewels

Ethical jewellery designer is crushing it with new collection Blooms that matches recycled aluminium with lab-grown gemstones

By Rachael Taylor

To transform aluminium drinks cans into jewellery, the discarded metal must first be cut into tiny squares before being melted at 600 degrees Celsius, at which temperature the coloured branding on the cans disappears. The aluminium is then refined to erase impurities before cooling to ingots, ready for the jewellery casting process.

“The biggest challenge with recycling aluminium cans is the impurities in the metal that causes issues with porosity, an uneven texture and tiny pores in the surface of the finished piece,” says Chan. “By refining the recycled aluminium, through a process of trial and error, we were able overcome this and actually take advantage of a controlled porosity that allow us to achieve greater colour intensity.”

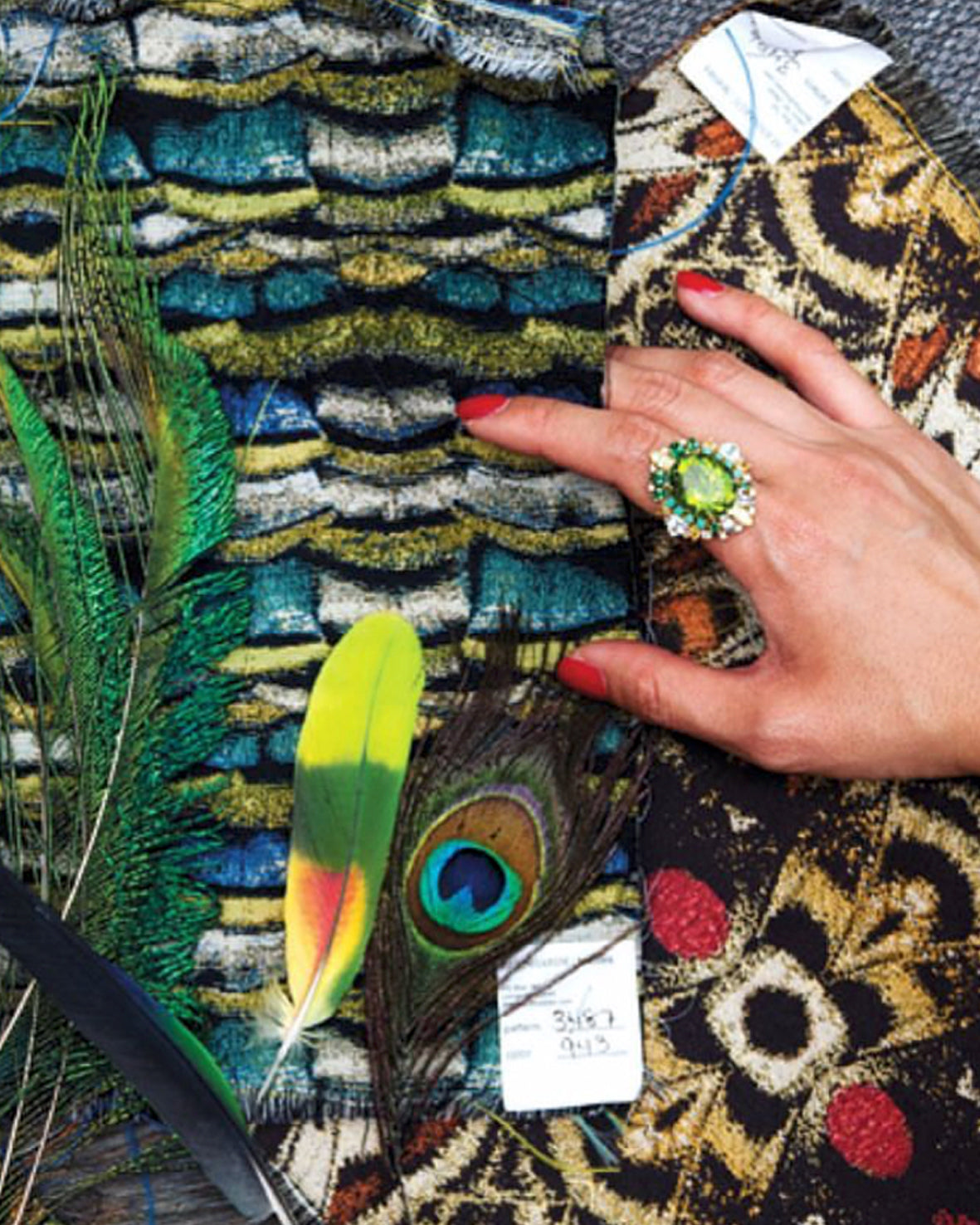

The result is a collection of jewels that offer up psychedelic, iridescent colours, achieved through a process called physical vapour disposition, or PVD; the same technique used to colour the bodywork of cars.

Though the techniques required to achieve these jewels are highly technical, what hits you when you see Blooms for the first time is not the science that fuels it – as impressive as it is – but the beauty of the jewels. These wildly radiant blooms will make a statement long before you have a chance to share the spectacular story of their creation.

From an ethical, technical and aesthetic viewpoint, the Anabela Chan Blooms collection is crushing it.

- Choosing a selection results in a full page refresh.